詳細(xì)說(shuō)明

上銀滾珠絲桿型號(hào)大全:

轉(zhuǎn)造級(jí)FSV系列:

R08-2.5B1

、R10-2.5B1

、R10-4B1、R12-4B1

、R16-5B1、R20-5C1、R25-5B2、R32-5B2、R32-10B2、R40-10B2、R50-10C2、R63-10C2

轉(zhuǎn)造級(jí)FSW系列:

R08-2.5B1、R10-2.5B1、R10-4B1、R12-4B1、R16-5B1、R20-5C1、R25-5B2、R25-10B1、R32-5B2、R32-10B2、R40-10B2、R50-10C2、R63-10C2

轉(zhuǎn)造級(jí)FSH系列:

R16-16S2、R16-16S4、R20-20S2、R20-20S4、R25-25S2、R25-25S4、 R32-32S2、R32-32S4

轉(zhuǎn)造級(jí)FSW系列:

R08-2.5B1、R10-2.5B1、R10-4B1、R12-4B1、R16-5B1、R20-5C1、R25-5B2、R25-10B1、R32-5B2、R32-10B2、R40-10B2、R50-10C2、R63-10C2

轉(zhuǎn)造級(jí)FSH系列:

R16-16S2、R16-16S4、R20-20S2、R20-20S4、R25-25S2、R25-25S4、 R32-32S2、R32-32S4

、R40-40S2、R40-40S4

、R50-50S2、R50-50S4

轉(zhuǎn)造級(jí)FSI系列:

R16-5T3

轉(zhuǎn)造級(jí)FSI系列:

R16-5T3

、 R20-5T3

、R20-5T4、R25-5T3

、R25-5T4、R25-10T3、R32-5T3、R32-5T4、R32-5T6、 R32-10T3、R32-10T4、R40-5T4、R40-5T6、R40-10T3、R40-10T4、R50-5T4、R50-5T6、 R50-10T3、R50-10T4、R50-10T6

研磨DFSV系列:

R16-16A2、R20-20A2、R25-25A2、R32-32A2

研磨DFSV系列:

R16-16A2、R20-20A2、R25-25A2、R32-32A2

、R40-40A2

研磨0FSW系列:

R16-5B1、 R16-5A1

研磨0FSW系列:

R16-5B1、 R16-5A1

、R20-5B1

、R20-5A2、R20-6B1

、R25-4B1、R25-4B2

、R25-5B1、R25-5A2

、R25-5C1

、 R25-6A2

、R25-6C1、R25-10A1

、R28-5B1

、R28-5B2、R28-6A2

、R32-5B1

、R32-5A2、 R32-5C1

、R32-6B1

、R32-6A2、R32-6C1

、R32-8B1、R32-8A2

、R32-8C1、R32-10B1、 R32-10A1、R32-12A1

、R32-12B1、R36-6B1

、R36-6B2、R36-10A1

、R36-16B1、R40-5B1

、 R40-5B2、R40-6B2

、R40-8B1、R40-8C1

、R40-10B1

、R40-10C1、R40-12B1

、R40-16A1

、 R45-10B1、R45-12B1

、R50-5A2

、R50-5A3、R50-6B2

、R50-8B1

、R50-8B2

、R50-10B2、 R50-10C1

、R50-12B1、R55-10C1

、R55-12B1、R63-8A2

、R63-10B2、R63-12B1

、R63-16B1、 R63-20A1

、R70-10B1、R70-12B1

、R36-20C1、R40-20C1

、R40-20B2、R45-20C1

、R45-20B2、 R45-25C1

、R50-20C1、R50-20B2

、R50-25C1

、R50-30C1

、R55-20C1、R55-20B2

、R55-25C1

、 R55-30C1

研磨FDV系列:

R16-5B1

研磨FDV系列:

R16-5B1

、R16-5B2、R16-5C1、R20-5B1、R20-5B2、 R20-6B1、R20-6C1、R25-5B1、R25-5B2、R25-5C1、R25-6B2

、R25-6C1、R25-10B1

、 R28-5B1、R28-5B2

、R28-6A2、R28-8A2

、R28-10B2、R32-5B1

、R32-5B2、R32-5C1

、 R32-6B1

、R32-6B2、R32-6C1

、R32-8B1、R32-8B2

、R32-8C1、R32-10B1、R32-10B2、 R32-10C1、R32-12A2、R32-12B1、R32-16A2、R36-6B1、R36-6B2、R36-10B2、R40-5B1、 R40-5B2、R40-6B2、R40-8B1、R40-8B2、R40-8C1、R40-10B1、R40-10B2、R40-10C1、 R40-12A2、R40-12B1、R40-12B2

、R40-12C1、R40-16A2

、R40-16B1、R40-20A1、R45-10B1、 R45-10B2、R45-12B2、R50-5A2、R50-5A3、R50-5B2、R50-6B2、R50-6B3、R50-8B1、 R50-8B2、R50-8B3、R50-10B2、R50-10B3、R50-10C1、R50-12B2、R50-12C1、R55-10C1、 R55-12B2、R63-8A2、R63-8A3、R63-10B2、R63-10B3、R63-12B2、R63-16B2、R63-20B2、 R70-10B2、R70-10B3

、R70-12B2

、R70-12B3、R80-10B2

、R80-10B3

、R80-12B2、R80-12B3

、 R80-16B2、R80-16B3

、R80-20B2、R80-20B3

、R100-12B2、R100-12B3

、R100-16B2、 R100-16B3、R100-20B2、R100-20B3

研磨FDW系列:

R16-5B2、R16-5B1、 R16-5C1、R20-5B1、R20-5B2、R20-6B1、R20-6C1、R25-5A2、R25-5B1、R25-5B2、R25-5C1、 R25-6B2、R25-6C1

研磨FDW系列:

R16-5B2、R16-5B1、 R16-5C1、R20-5B1、R20-5B2、R20-6B1、R20-6C1、R25-5A2、R25-5B1、R25-5B2、R25-5C1、 R25-6B2、R25-6C1

、R25-10B1、R28-5B1

、R28-5B2、R28-6A2

、R28-6B2、R32-4B2

、 R32-5B1、R32-5B2

、R32-5C1、R32-6B1

、R32-6B2、R32-6C1

、R32-8A2、R32-8B1

、R32-8B2、 R32-8B3

、R32-8C1、R32-10A2

、R32-10B1、R32-10B2

、R32-10C1、R32-12B1

、R32-12B2、 R32-12C1

、R36-6B1

、R36-6B2

、R36-12A2

、R36-12B1、R36-10B2

、R36-12B2、R36-8A2

、 R36-8B2、R40-5B1

、R40-5B2、R40-6B2

、R40-8B1、R40-8B2

、R40-8B3、R40-8C1

、 R40-10A2、R40-10B1

、R40-10B2

、R40-10C2

、R40-12A2

、R40-12B1、R40-12B2

、R40-12C1、 R40-16A2、R40-16B1

、R40-16B2、R45-10B1

、R45-10B2

、R45-12B2、R45-16B2

、R50-5A2

、 R50-5A3、R50-6B2

、R50-6B3

、R50-8B1、R50-8B2

、R50-8B3、R50-10B1

、R50-10B2、 R50-10B3

、R50-10C1、R50-12B1

、R50-12B2、R50-12C1

、R50-16B2、R50-20B1、R55-10C1、 R55-12B2、R63-8A2、R63-8A3、R63-10B2、R63-10B3、R63-12B2、R63-16B2、R63-20B2、 R70-10B2、R70-10B3、R70-12B2、R70-12B3

、R70-20B3

、R80-10B2、R80-10B3

、R80-12B2

、 R80-12B3、R80-16B2

、R80-16B3

、R80-20B2

、R80-20B3

、R100-12B2

、R100-12B3、 R100-16B2

、R100-16B3

、R100-20B2、R100-20B3

研磨FDI系列:

R16-5T3、 R16-5T4、R20-5T3、R20-5T4、R20-6T3、R20-6T4、R25-2.5T5、R25-5T3、R25-5T4、 R25-6T3、R25-6T4、R25-10T3、R28-5T5、R28-10T4、R32-2.5T6、R32-5T3、R32-5T4、 R32-5T6、R32-5.08T4、R32-6T3、R32-6T6、R32-8T3、R32-8T4、R32-10T4、R40-5T4、 R40-5T6

研磨FDI系列:

R16-5T3、 R16-5T4、R20-5T3、R20-5T4、R20-6T3、R20-6T4、R25-2.5T5、R25-5T3、R25-5T4、 R25-6T3、R25-6T4、R25-10T3、R28-5T5、R28-10T4、R32-2.5T6、R32-5T3、R32-5T4、 R32-5T6、R32-5.08T4、R32-6T3、R32-6T6、R32-8T3、R32-8T4、R32-10T4、R40-5T4、 R40-5T6

、R40-6T4、R40-6T6、R40-8T4、R40-8T6、R40-10T3、R40-10T4、R40-10T5、 R40-12T3、R40-12T4、R45-10T4、R45-12T3、R45-16T3、R50-5T4、R50-5T6、R50-6T4、 R50-6T6、R50-8T4、R50-8T6、R50-10T3、R50-10T4、R50-10T6、R50-12T3、R50-12T4、 R63-6T4、R63-6T6

、R63-8T4、R63-8T6

、R63-10T6、R63-12T4

、R63-12T6、R80-10T4

、 R80-10T6、R80-12T4

、R80-12T6、R80-16T3

、R80-16T4、R80-20T3

、R80-20T4、 R100-12T4、R100-12T6、R100-16T4、R100-16T6、R100-20T4

研磨FSV系列:

R16-4B2、 R16-5B1、R16-5B2、R16-5C1、R16-10B1

研磨FSV系列:

R16-4B2、 R16-5B1、R16-5B2、R16-5C1、R16-10B1

、R20-5B1、R20-5B2

、R20-6B1、R20-6C1

、 R20-20A1、R25-5B2

、R25-5C1、R25-6B2

、R25-6C1、R25-8B1、R25-10B1

、R25-10B2、 R25-16B1

、R25-20B1、R25-25A1

、R28-5B1

、R28-5B2

、R28-6A2

、R28-6B2

、R32-5B2

、 R32-5C1、R32-6B2

、R32-6C1、R32-8B2

、R32-8C1、R32-10B1

、R32-10B2、R32-10C1

、 R32-16B1

、R32-20B1、R32-25B1

、R32-32A1

、R36-6B1、R36-6B2

、R36-10B2、R40-5B2

、 R40-6B2

、R40-8B2

、R40-8C1、R40-10B1

、R40-10C1、R40-12B2

、R40-16B2、R40-25B1、 R40-32B1

、R40-40A1、R45-10B1、R45-10B2、R45-12B2

、R50-5A2、R50-5A3、R50-6B2

、 R50-6B3、R50-8B2

、R50-8B3、R50-10B2

、R50-10B3、R50-10C1

、R50-12B1、R50-12B2

、 R50-12C1、R50-40A1

、R50-50A、R55-10C1

、R55-12B2、R55-20B2

、R63-8A2、R63-8A3

、 R63-10B2、R63-10B3、R63-12B2、R63-16B2、R63-20B2、R63-20B3、R70-10B2、R70-10B3、 R70-12B2、R70-12B3、R80-10B2、R80-10B3、R80-12B2、R80-12B3、R80-16B2、R80-16B3、 R80-20B2、R80-20B3、R100-12B2

、R100-12B3、R100-16B2

、R100-16B3、R100-20B2

、 R100-20B3

研磨FSW系列:

R12-4B1、R12-4C1

研磨FSW系列:

R12-4B1、R12-4C1

、R12-5B1

、R14-5B1、R15-10A1、 R15-20A1、R16-4B1、R16-5B1、R16-5B2、R16-5C1、R20-5B1、R20-5B2、R20-6B1、 R20-6C1、R25-4B2、R25-5B2、R25-5C1、R25-6B1、R25-6B2、R25-6C1、R25-10B1、 R25-10B2、R25-12B1、R28-5B1、R28-5B2、R28-6A2、R28-12B2、R28-16B1、R32-5B2、 R32-5C1、R32-6B2、R32-6C1

、R32-8B2、R32-8C1

、R32-10B2

、R32-10C1

、R32-12A2、 R32-12B2、R32-16A2、R32-16B1、R32-16B2、R32-20A2、R32-20B1、R36-6B1、R36-6B2、 R36-10B2、R36-12B2、R36-16C、R40-5B2、R40-6B2、R40-8B2、R40-8C1、R40-10B2、 R40-10C1、R40-12B1、R40-12B2、R40-16A2

、R40-16B1、R45-10B1

、R45-10B2、R45-12B2

、 R50-5A2

、R50-5A3、R50-6B2

、R50-6C2

、R50-6B3

、R50-8B2

、R50-8B3、R50-10B2

、 R50-10B3、R50-10C1

、R50-12B1、R50-12B2

、R50-12C1、R50-30A2

、R55-10B2、R55-10C1、 R55-12B2、R60-12B2

、R63-8A2

、R63-8A3、R63-10B2

、R63-10B3、R63-12B2

、R63-16B2、 R63-20B2

、R70-10B2

、R70-10B3、R70-12B2

、R70-12B3、R80-10B2

、R80-10B3、R80-12B2

、 R80-12B3

、R80-16B2

、R80-16B3

、R80-20B2、R80-20B3

、R100-12B2、R100-12B3

、 R100-16B2、R100-16B3

、R100-20B2、R100-20B3

研磨FSH系列:

R15-20S1

研磨FSH系列:

R15-20S1

、 R16-16S2、R16-16S4

、R16-16S2、R16-16S4

、R20-20S2、R20-20S2

、R20-20S4、R25-25S2

、 R25-25S4

、R32-32S2、R32-32S4

、R40-40S2、R40-40S4

、R50-50S2、R50-50S4

研磨FSI系列:

R8-2.5T3

研磨FSI系列:

R8-2.5T3

、 R14-2.54T3

、R14-4T3

、R16-2T3

、R16-2.5T4

、R16-5T3、R16-5T4

、R16-6T4、R20-2T6、 R20-2T4、R20-2.5T5、R20-2.54T6、R20-4T3、R20-5T3、R20-5T4、R20-6T3、R20-6T4、 R20-10T3

、R25-2T6

、R25-2T4

、R25-2T3、R25-2.5T5

、R25-4T4

、R25-5T3、R25-5T4

、 R25-5T5

、R25-5T6

、R25-6T3、R25-6T4

、R25-10T3、R25-10T4

、R32-5T3、R32-5T4

、 R32-5T6、R32-6T3

、R32-6T4、R32-6T6、R32-8T3、R32-8T4、R32-10T3、R32-10T4、 R40-5T4、R40-5T6、R40-5.08T6、R40-6T4、R40-6T6、R40-8T4、R40-8T6、R40-10T3、 R40-10T4、R50-5T4、R50-5T6、R50-6T4、R50-6T6、R50-8T4、R50-8T6、R50-10T3、 R50-10T4

、R50-10T6、R50-12T3

、R50-12T4、R50-20T4、R63-6T4、R63-6T6、R63-8T4、 R63-8T6、R63-10T4、R63-10T6、R63-12T4、R63-12T6、R80-10T4、R80-10T6、R80-12T4、 R80-12T6、R80-16T3、R80-16T4、R80-20T3、R80-20T4、R100-12T4、R100-12T6、 R100-16T4、R100-16T6

、R100-20T4

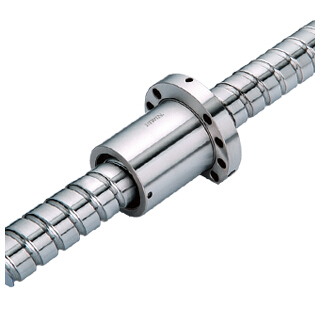

HIWIN滾珠絲杠(滾珠螺桿)在使用上有很多的優(yōu)點(diǎn),舉凡高效率

HIWIN滾珠絲杠(滾珠螺桿)在使用上有很多的優(yōu)點(diǎn),舉凡高效率

、可逆性、零背隙

、高剛性,導(dǎo)程精度高及其他多項(xiàng)優(yōu)點(diǎn)

,與傳統(tǒng)艾克姆螺桿(ACME)相比較,滾珠絲杠(滾珠螺桿)在螺桿與螺帽間

,加入鋼珠。將傳統(tǒng)螺桿的滑動(dòng)摩擦傳動(dòng)以鋼珠滾動(dòng)運(yùn)動(dòng)取代。

中文名上銀絲杠 優(yōu)點(diǎn):高效率、可逆性、零背隙、高剛性 特征:有助于維持高效率及高精度特點(diǎn)零背隙及高剛性

上銀滾珠絲杠特征及應(yīng)用:

以大大降低摩擦損耗,有助于維持高效率及高精度。下列詳述HIWIN滾珠螺桿的各項(xiàng)特性及優(yōu)點(diǎn)。

1.高效率及可逆性

由于滾珠絲杠(滾珠螺桿)螺桿軸及螺帽均是點(diǎn)接觸之滾動(dòng)運(yùn)動(dòng),所以其效率可高達(dá)90%以上。因此其傳動(dòng)扭矩僅只有傳統(tǒng)導(dǎo)螺桿的1/3,滾珠螺桿的機(jī)械效率遠(yuǎn)高于傳統(tǒng)導(dǎo)螺桿。

HIWIN滾珠絲杠(滾珠螺桿)在牙型表面采以超精密加工

中文名上銀絲杠 優(yōu)點(diǎn):高效率、可逆性、零背隙、高剛性 特征:有助于維持高效率及高精度特點(diǎn)零背隙及高剛性

上銀滾珠絲杠特征及應(yīng)用:

以大大降低摩擦損耗,有助于維持高效率及高精度。下列詳述HIWIN滾珠螺桿的各項(xiàng)特性及優(yōu)點(diǎn)。

1.高效率及可逆性

由于滾珠絲杠(滾珠螺桿)螺桿軸及螺帽均是點(diǎn)接觸之滾動(dòng)運(yùn)動(dòng),所以其效率可高達(dá)90%以上。因此其傳動(dòng)扭矩僅只有傳統(tǒng)導(dǎo)螺桿的1/3,滾珠螺桿的機(jī)械效率遠(yuǎn)高于傳統(tǒng)導(dǎo)螺桿。

HIWIN滾珠絲杠(滾珠螺桿)在牙型表面采以超精密加工

,以降低珠槽與鋼珠間的接觸摩擦

,又鋼珠與珠槽間為點(diǎn)接觸之滾動(dòng)運(yùn)動(dòng)

,有低摩擦力及高運(yùn)轉(zhuǎn)效率的優(yōu)

點(diǎn)。故可降低馬達(dá)驅(qū)動(dòng)力要求

點(diǎn)。故可降低馬達(dá)驅(qū)動(dòng)力要求

,進(jìn)而降低成本。HIWIN以高精度測(cè)試儀器并依循標(biāo)準(zhǔn)測(cè)試步驟以確保滾珠螺桿的效率

。

2.零背隙及高剛性

CNC 工具機(jī)、IT及半導(dǎo)體設(shè)備對(duì)于傳動(dòng)螺桿的要求為零背隙

2.零背隙及高剛性

CNC 工具機(jī)、IT及半導(dǎo)體設(shè)備對(duì)于傳動(dòng)螺桿的要求為零背隙

、最小彈性變形(高剛性)及高順暢感,經(jīng)由我們的特別設(shè)計(jì)可以達(dá)成此一要求

。滾珠絲杠(滾珠螺桿)及 HIWIN直線導(dǎo)軌、HIWIN導(dǎo)軌采用施加預(yù)壓力

,來(lái)達(dá)到綜欣機(jī)臺(tái)的重現(xiàn)性及全行程的高剛性。但過(guò)大的預(yù)壓力